- Home

- Products

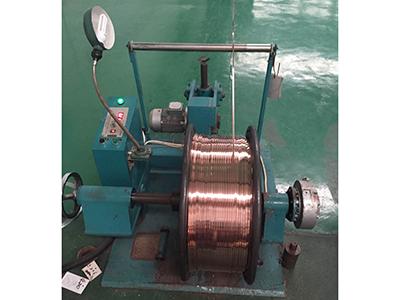

- Casting Machines

- Polyimide Film Concentric Taping and Sintering Machine

Polyimide Film Concentric Taping and Sintering Machine

Production scope

One machine with one product line

Feedstock: section: 10~80 mm2

Concentric film tapping heads

Wrap bobbin size: outer dia. Φ330mm, inner dia. ø76mm, lock film width 10~130mm

Supply voltage: 415v 50Hz

Direction: right (enter), left (exit), when facing the machine

Equipment composition and the technical specification

Composed with: Pay off, the main machine: felt locator, straightening device, polishing dust removal device, hot air dry device, concentric taping film head (1 head, 1 film), carter pillar traction device, removable high frequency generator (with infrared sensor), high-frequency generator water recycling device, high temperature resistant quadrilateral pressure device (the first), small radiation furnace, high temperature resistant quadrilateral pressure device (the second), small radiation furnace, high temperature resistant quadrilateral pressure device (the third), cool water groove, hot air dry unit, felt locator, carter pillar tractor device, roller type measure meters unit, and take up.

PS-800 pay off 1unit

Electric lifting wooden bobbin (magnetic powder brake)

Lift type up and down

Clamping type Plunger type

Carrying weight max. 800 kg

No need for automatic winding

Straightening device: 1 set

Straightening rollers: 10 pieces

Roller diameter: 47 mm

Roller distance: 70 mm

Materials of roller: Nylon

Traction device: 1 set

Contact length: 320 mm

Traction belt type: cog belt

Traction Band Width: 40 mm

Traction belt material: high strength

resistant rubber

Traction drive: servo drive

Clamping method: Pneumatic

Maximum traction: 500 kg

The maximum distance of the traction belt: 40 mm

Synchronization: Servo control

Four sides polishing cleaning device: 1 set

Each set of four sides polishing cleaning device has

4 motor (0.25kw), arranged 90 degree,

clean the burrs and the oxidation layer on the copper wire.

Cleaning materials: Nylon brush

Brush running speed: 1440 round

Hot air circulating device: 1 set

Electric heat power: 5 kw, fan power: 0.25KW

Film tapping heads: 1 set

Wrap type: concentric film tapping head. Each taping head can wrap 1 layer of film.

Wrap direction of turning: Each wrapping head can be positive rotation and inversion and stop. It can achieve gap wrap, seam wrap, 1/2 or 2/3 overlap. Wrap pitch is adjustable.

Wrapping rated speed: 1000 rpm/min

Wrapping pitch drift distance: ≤±0.2mm

Pitch adjust type: We will add you a fine pitch switch to adjust the pitch slightly. It has two courses to set value: If you want to set 2.5mm, first you can set 2 in the first course, then on the second course, you can set 5mm, when you want to set 2.6mm, you just need to add the second course 1mm.

Tension control type of film: Each wrapping head is equipped

with servo motor constant tension device and automatic stop

of film break.

Each wrapping head can install 1 tray with tape. The maximum outer diameter of tray is 300mm. The hole diameter of tray is 76mm.

Each winding head can be installed 1 tray with a tape. The maximum diameter is 300mm, with a disk diameter of 76mm.

Each film wrapping head has its own protective cover, with soft lighting.

The guide wheel will be used for fixing the wire core, the material of guide wheel, skeleton of warping head, conduction band structure aluminum alloy, surface oxidation.

Wrap drive type: servo drive

Lock: Germany cross-linking lock

High-frequency generator: 1 set

The model is GP-45B high-frequency generator. It has sintering delay and start in advance function, power 45 kilowatts, in order to ensure the start and stop this line sintering quality, high frequency as a whole mobile. After the shutdown, the high-frequency move forward as a whole, the device once again boot, the high frequency as a whole slowly returned to the original position, (moving distance of 100 to 250 mm, the actual distance to the length of the tuner) mobile mode with the reducer screw way.

High temperature resistant quadrilateral pressure device: 3 sets

Clamping roller has a diameter of 90 mm. Material is silicon rubber. Up and down adjustment is pneumatic clamping. The left and right adjustment has two kinds of adjustment. Small size suits for manual adjustment. Big size suits for pneumatic adjustment. As you can see in the picture, we can use pneumatic adjustment on the one side, and you can use manual screw adjustment, which can ensure it can use both types of adjustment type. It includes three sets of high frequency indicator, which is good for adhering to the thin film and bare copper wire and eliminate bubbles. The bottom can be adjusted, and the wheel can be used many times.

Small radiation furnace: 2 sets

Stainless steel plate with a length of 4 meters has divided the furnace into two sections. The furnace has three stainless steel heating tubes, and each tube has a power of 1.2 kilowatts. The overall movement of the oven is electric, and 2 sections of oven with 1 set of temperature controller are placed separately. It can adjust the oven temperature individually. When the belt is broken, the oven will automatically move away from the heat source. In the event of power failure, you can also use the hand wheel to remove and to prevent product baking.

Small radiation furnace don’t need shelf, only stainless steel board. The heating furnace can be used with far infrared sensor, which can control the temperature automatically.

Cool water groove: 1 set

Made of stainless steel, 1.2 meter in length

Hot air dry unit: 1 set

Little hot air dry unit power 0.75 kw, dry water stains.

Cater pillar: 1 set 1120 model

Contact length: 320 mm

Shape of belt: cog belt

Belt width: 40mm

Belt material: high strength resistant rubber

Caterpillar drive: servo driven

Clamping method: pneumatic

Max. pulling force: 500kgs

Max. opening distance of traction: 40mm

Synchronization: servo control

Two sets of traction device adopt synchronizing signal. Take up type adopts speed mode and torque mode, take up part and encoder is synchronizing signal.

When press the stop button, the wrapping head and traction device will be stopped together, and will not interrupt the wrapping part.

As for the belt’s color, we will send you the color card, so you can choose one that’s right for you.

Meter measuring device: 1 set

Digital display, by the contact wire of guide (nylon) wheel to count, when reach the setting length, the machine stopped automatically.

Take-up: 1 set