- Home

- Products

- Casting Machines

- Oxygen Free Copper Rod Upward Continuous Casting Machine

Oxygen Free Copper Rod Upward Continuous Casting Machine

Usage

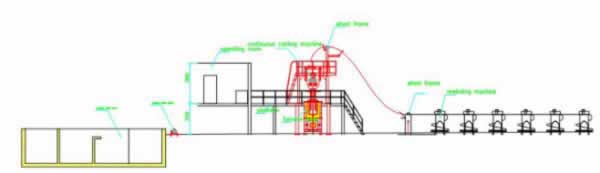

The oxygen free copper rod upward continuous casting machine was designed for the production of 8-20mm copper rods. The equipment can use various types of copper including qualified scrap copper products. Compared to black copper rods produced by traditional manglers from copper ingots, the rods produced by our casting technology are of higher quality with lower production costs and minimal pollution during operation.

Main Composed Parts

1) Induction furnace

The induction furnace of the continuous casting machine features adjustable voltage from 90V to 420V. The large current flow in the copper rings of the furnace heat the copper until it becomes molten for further casting.

The continuous casting machine is the main part of the system. The casting equipment uses a drawing mechanism made up of an AC servo motor and two drawing rollers. The rollers can reach 0-1000 rpm to draw up the copper rods in continuous fashion. The liquid level guarantees that the crystallizer insert ed into the copper liquid is relatively stable. The crystallizer effectively cools the molten copper rod by heat exchange.

There is a speed control device between casting machine and take-up machine to synchronize casting speed and take-up speed with frequency changers.

3) Double-head take-up machine

4) Water cooling system

The water cooling system of the copper rod machine allows the casted copper to cool in a controlled manner for the production of high quality copper rods.

5) Electrical control system

The main machine control system is composed of a traction motor, an elevator motor and their electrical control system. The traction motor uses a stand-alone control system. Every double-head winding machine is controlled separately. A take-up control panel is fixed in the frame of the double-head winding machine. Its control knob is fixed on the surface of the frame. The water-cooled electrical system is a control box hung on the wall of the water pump chamber. It can control two water pumps.

| 1 | Density | 8.9kg/dm^3 |

| 2 | Tensile strength | >170N/m㎡ |

| 3 | Elongation | >35% |

| 4 | Electrical conductivity | no less than 100%IACS (2mm dia soft wire) |

| 5 | Oxygen content | ≤ 10ppm |

| No. | Type | Strand Qty | Product Dia.(mm) | Output (T/Y) |

| 1 | F6-Q3-8/20 | 6 | 8-20 | 3000 |

| 2 | F8-Q4-8/20 | 8 | 8-20 | 4000 |

| 3 | F10-Q5-8/20 | 10 | 8-20 | 5000 |

| 4 | F12-Q6-8/20 | 12 | 8-20 | 6000 |

| 5 | F16-Q12-8/20 | 16 | 8-20 | 12000 |